High-Quality Pallet Moulds: A Complete Guide

By:Admin

Pallet Mould is dedicated to providing its clients with the best products and services in the industry. The company's team of skilled engineers and designers work tirelessly to develop innovative mold designs that meet the specific needs of their clients. With a focus on precision and quality, Pallet Mould ensures that each mold is crafted with care and attention to detail.

In addition to its commitment to excellence, Pallet Mould also prides itself on its ability to deliver custom mold solutions to its clients. Whether a client requires a custom mold design or a modification to an existing mold, Pallet Mould has the expertise and technology to meet their needs. This flexibility and versatility have earned the company a loyal and satisfied client base.

Pallet Mould's dedication to quality and customer satisfaction has garnered the attention of industry leaders and experts. The company's molds are highly regarded for their durability, precision, and efficiency. As a result, Pallet Mould has become a trusted partner for businesses in a variety of industries, including logistics, manufacturing, and transportation.

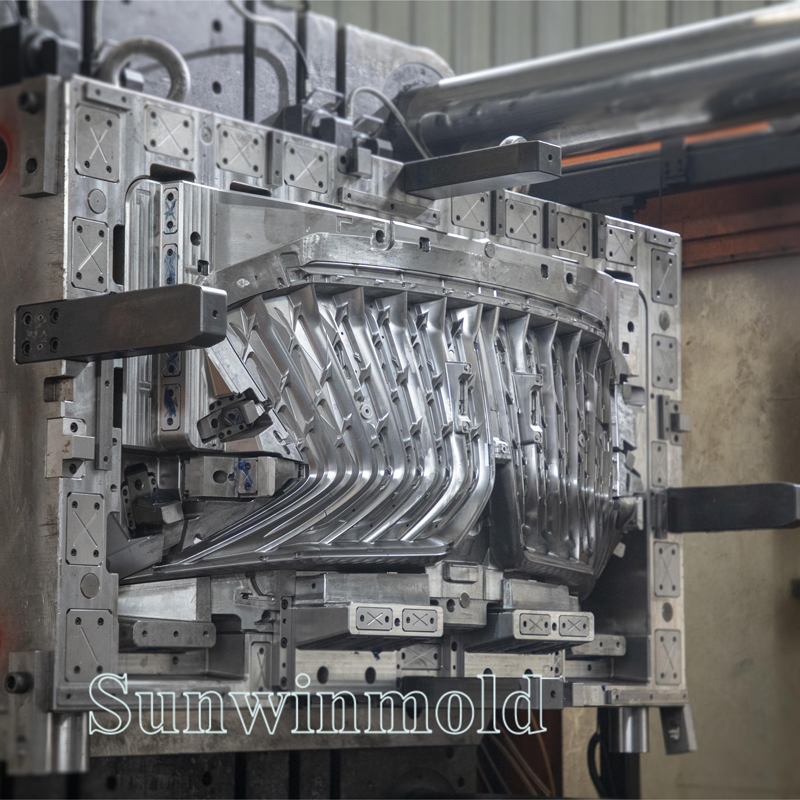

One of Pallet Mould's most sought-after products is their plastic pallet mold. These molds are designed to produce durable and reliable plastic pallets that are essential in the logistics and transportation industry. With a focus on strength and durability, Pallet Mould's plastic pallet molds have become a staple for businesses looking to streamline their operations and reduce costs.

Pallet Mould's plastic pallet molds are highly versatile and can be customized to meet the unique requirements of each client. Whether a client needs a certain size, shape, or weight capacity, Pallet Mould has the expertise to deliver a mold that meets their specifications. This customization capability has made Pallet Mould a go-to source for businesses looking to optimize their pallet production processes.

In addition to its plastic pallet molds, Pallet Mould also offers a wide range of other mold solutions, including injection molds, extrusion molds, and blow molds. With a diverse portfolio of products, the company is able to cater to the unique needs of clients across various industries. Whether a client needs a simple mold or a complex, multi-cavity mold, Pallet Mould can deliver a solution that meets their demands.

As a testament to its dedication to quality, Pallet Mould utilizes advanced technology and cutting-edge manufacturing processes to produce its molds. The company's state-of-the-art facilities and equipment ensure that each mold is crafted with precision and efficiency. This commitment to technology and innovation has positioned Pallet Mould as a leader in the industry.

Overall, Pallet Mould's combination of expertise, innovation, and commitment to quality has set the company apart as a premier provider of plastic pallet molds and other mold solutions. With a focus on customization, durability, and efficiency, Pallet Mould continues to exceed the expectations of its clients and solidify its position as a trusted partner in the industry.

In conclusion, Pallet Mould's dedication to excellence and innovation has made it a standout in the mold manufacturing industry. By delivering high-quality and customizable mold solutions, the company has earned the trust and loyalty of clients across various industries. With a focus on durability, precision, and efficiency, Pallet Mould is well-positioned to continue its success and maintain its status as a leader in the industry.

Company News & Blog

How to Get Custom Soft Plastic Molds for Your Business

Custom Soft Plastic Molds, a leading manufacturer of high-quality plastic molds, has quickly become a key player in the industry. With a focus on innovation and customer satisfaction, the company has established itself as a trusted partner for businesses in a wide range of sectors.Founded in [year], Custom Soft Plastic Molds has quickly risen through the ranks to become one of the most reputable manufacturers of soft plastic molds. The company prides itself on its ability to deliver top-notch products that meet the unique needs of its clients. Whether it's creating molds for prototypes, small production runs, or large-scale manufacturing, Custom Soft Plastic Molds has the expertise and experience to get the job done right.The company's success can be attributed to several key factors. Firstly, Custom Soft Plastic Molds places a strong emphasis on utilizing the latest technology and techniques in their manufacturing processes. This allows them to produce molds that are not only of the highest quality but also highly precise and efficient. Additionally, the company's team of experienced engineers and designers work closely with clients to develop customized solutions that perfectly align with their specific requirements.Another important aspect of Custom Soft Plastic Molds' success is their commitment to customer satisfaction. The company understands that each client has unique needs and works tirelessly to ensure that their expectations are not only met but exceeded. This dedication to customer service has helped them build long-lasting relationships with clients from a wide range of industries, including automotive, medical, consumer goods, and more.In addition to their commitment to quality and customer satisfaction, Custom Soft Plastic Molds also places a strong emphasis on sustainability. The company is dedicated to minimizing its environmental impact and regularly invests in eco-friendly practices and materials. This commitment to sustainability has not only helped the company reduce its carbon footprint but has also positioned it as a leader in environmentally conscious manufacturing.To further solidify its position as an industry leader, Custom Soft Plastic Molds continues to invest in research and development. The company is constantly exploring new materials, techniques, and technologies to enhance its capabilities and offer even better solutions to its clients. This commitment to innovation has allowed Custom Soft Plastic Molds to stay ahead of the curve and remain a top choice for businesses looking for cutting-edge plastic molding solutions.Looking to the future, Custom Soft Plastic Molds is poised for even greater success. With a solid foundation built on quality, customer satisfaction, and innovation, the company is well-positioned to continue its upward trajectory. By staying true to its core values and embracing new opportunities, Custom Soft Plastic Molds is set to further solidify its position as a key player in the industry.In conclusion, Custom Soft Plastic Molds has quickly become a leader in the manufacturing of high-quality plastic molds. Through its commitment to quality, customer satisfaction, sustainability, and innovation, the company has established itself as a trusted partner for businesses in a wide range of industries. As it continues to grow and expand its capabilities, Custom Soft Plastic Molds is well-positioned for even greater success in the future.

Understanding the Cost of Custom Plastic Molding: What You Need to Know

Custom plastic molding is an essential process in the manufacturing industry. It involves the creation of custom plastic parts and products using a mold that is designed to the specific requirements of a customer. The process is widely used across various industries, including automotive, medical, electronics, and consumer goods.{Company name}, a leading manufacturer specializing in custom plastic molding, has been gaining recognition for its expertise and high-quality products. The company has a state-of-the-art facility equipped with advanced machinery and a team of skilled professionals who are dedicated to delivering top-notch custom plastic molding solutions to their customers.One of the key factors to consider when it comes to custom plastic molding is the cost. The cost of custom plastic molding can vary depending on a number of factors such as the complexity of the part, the material used, and the quantity of parts required. It is essential for companies to partner with a reliable and experienced manufacturer that can provide cost-effective solutions without compromising on quality.{Company name} understands the importance of cost-effectiveness in custom plastic molding and has streamlined its processes to offer competitive pricing to its customers. The company utilizes the latest technology and efficient production methods to optimize the manufacturing process and reduce overall production costs. This allows them to offer high-quality custom plastic molding solutions at a competitive price point.The cost of custom plastic molding is affected by various factors, including the choice of material. Different types of plastics have different properties and costs, and the selection of the right material is crucial in achieving the desired functionality and durability of the final product. {Company name} works closely with its customers to determine the most suitable material for their custom plastic molding needs, taking into account factors such as strength, flexibility, and cost.Another significant factor that impacts the cost of custom plastic molding is the complexity of the part. Intricate designs and complex geometries can increase the manufacturing time and may require additional tooling, which can affect the overall cost. {Company name} has the expertise and capabilities to produce custom plastic parts with complex designs, offering cost-effective solutions without sacrificing quality.Furthermore, the quantity of parts required also plays a crucial role in determining the cost of custom plastic molding. {Company name} has the capacity to handle both small and large volume production runs, offering competitive pricing for high-volume orders to meet the diverse needs of its customers. The company's efficient production processes allow for cost savings on larger orders, making them an ideal partner for businesses looking to minimize custom plastic molding costs.{Company name} also provides value-added services such as design assistance, material selection, and prototyping to help customers optimize their custom plastic molding projects and reduce overall costs. The company's team of experienced engineers and designers work closely with customers to refine their designs and identify cost-saving opportunities without compromising on quality.In conclusion, {Company name} is committed to providing cost-effective custom plastic molding solutions without compromising on quality. The company's dedication to leveraging advanced technology, efficient production methods, and value-added services allows them to offer competitive pricing to their customers while delivering high-quality custom plastic molding products. Whether it's for the automotive, medical, electronics, or consumer goods industries, {Company name} is a trusted partner for businesses looking to minimize their custom plastic molding costs.

Innovative TPU Injection: a Breakthrough in Manufacturing Technology

Title: Revolutionary TPU Injection Technology Set to Transform IndustriesIntroduction:As industries continue to evolve and innovate, new materials and technologies are emerging to cater to the ever-growing demands. One such breakthrough is the revolutionary TPU Injection technology developed by [company name]. This cutting-edge technique has the potential to transform various industries, enhancing product performance, durability, and overall customer satisfaction.In collaboration with renowned researchers and materials experts, [company name] has successfully harnessed the power of TPU Injection to create advanced solutions catering to a wide range of applications. With its exceptional versatility, TPU Injection is poised to revolutionize industries such as automotive, footwear, electronics, and sports equipment.TPU Injection: Superior Characteristics and Advantages:Thermoplastic polyurethane (TPU) is a polymer renowned for its remarkable mechanical properties, including high abrasion and chemical resistance, flexibility, and excellent structural integrity. TPU Injection amplifies these characteristics, allowing for the creation of products that are not only durable but also lightweight.One of the key advantages of TPU Injection lies in its ability to seamlessly mold complex shapes and designs. This technique offers manufacturers the flexibility to produce intricate parts with precision, ensuring an ideal fit and finish. Additionally, TPU Injection allows for the integration of various colors and textures, further enhancing the aesthetics of the final products.Automotive Industry: Reinventing Vehicle ComponentsAutomakers are constantly seeking ways to improve vehicle performance, safety, and comfort. TPU Injection presents new opportunities in this industry by offering enhanced solutions for automobile components. With its superior wear resistance and flexibility, TPU Injection is ideal for manufacturing durable and comfortable automotive interiors, including seat covers, dashboard panels, and steering wheels.Furthermore, TPU Injection can be utilized in producing exterior parts such as bumper covers and protective trim. The material's ability to withstand extreme weather conditions, temperature fluctuations, and impact make it an ideal choice for creating long-lasting and aesthetically pleasing automotive components.Footwear Industry: Transforming Comfort and PerformanceThe footwear industry demands materials that provide exceptional comfort, flexibility, and durability. TPU Injection satisfies these requirements and offers numerous advantages in shoe manufacturing. By utilizing TPU Injection, manufacturers can create ergonomic shoe soles, providing superior shock absorption and cushioning. This enables athletes and everyday users alike to experience enhanced comfort and support.Moreover, TPU Injection technology allows for the seamless integration of specialized features such as anti-slip properties and water resistance. The result is footwear that not only performs well under various conditions but also keeps users safe and comfortable throughout the day.Electronics Industry: Elevating Device Protection and FunctionalityIn the rapidly evolving electronics industry, device durability and protection are of paramount importance. TPU Injection holds immense potential for improving the performance and longevity of electronic devices. By incorporating TPU Injection in the production of phone cases, tablet covers, and smartwatch bands, manufacturers can offer customers increased impact resistance and shock absorption.TPU Injection also enables the creation of protective films for electronic displays, providing scratch resistance without compromising clarity. Additionally, the material's high flexibility allows for the development of foldable displays and wearables, further expanding design possibilities in the electronics sector.Sports Equipment Industry: A Game-Changer for AthletesAthletes and sports enthusiasts demand equipment that enhances their performance and ensures their safety. TPU Injection plays a transformative role in the sports equipment industry by providing unparalleled strength, stability, and protection. From hockey shin guards to football helmets, TPU Injection can be utilized to create lightweight and durable gear that mitigates the risk of injuries.Furthermore, TPU Injection's ability to mold multi-layer structures facilitates the development of custom-fit padding and cushioning for sportswear and equipment. This ensures maximum comfort and performance enhancement, giving athletes a competitive edge.Conclusion:With its exceptional properties and remarkable versatility, TPU Injection is set to revolutionize various industries, from automotive to electronics, from footwear to sports equipment. As [company name] harnesses the capabilities of this groundbreaking technology, we can expect to witness the birth of innovative products that offer superior performance, durability, and customer satisfaction. Industries will be forever transformed by the limitless possibilities unlocked through TPU Injection, marking a new era of innovation and progress.

Create Your Own Resin Mold for Perfume Bottles and Unleash Your Creativity

Perfume Bottle Resin Mold is a new product that has captured the attention of the market in recent months. This innovative mold has been designed to help create custom perfume bottles using resin, allowing for a unique and personalized touch to the final product. With its easy-to-use design and high-quality materials, the Perfume Bottle Resin Mold has quickly become a favorite among DIY enthusiasts and professionals in the fragrance industry.The Perfume Bottle Resin Mold is manufactured by a leading company in the arts and crafts industry. Their commitment to quality and innovation has led to the development of a wide range of products that cater to the needs of creative individuals. With a strong emphasis on user-friendly designs and durable materials, the company has established itself as a trusted name in the market.The Perfume Bottle Resin Mold is a testament to the company's dedication to providing innovative solutions for creative projects. It is crafted with precision and attention to detail, ensuring that users can create flawless perfume bottles with ease. The mold is made from high-quality materials that are resistant to wear and tear, allowing for multiple uses without compromising on the end result.One of the key features of the Perfume Bottle Resin Mold is its versatility. It can be used to create a wide variety of perfume bottle designs, from sleek and modern to intricate and decorative. This flexibility has made it a valuable tool for artists and designers who are looking to add a personal touch to their fragrance products. Whether it's for personal use or commercial production, the Perfume Bottle Resin Mold offers endless possibilities for customization.The company behind the Perfume Bottle Resin Mold is dedicated to ensuring that their products are accessible to all. They have made it a priority to keep their prices competitive, without compromising on quality. This commitment to affordability has made the Perfume Bottle Resin Mold an attractive option for businesses and individuals alike, as they seek to create unique and memorable fragrance products.In addition to its high-quality materials and affordable pricing, the Perfume Bottle Resin Mold is also designed for ease of use. It comes with clear and simple instructions, making it accessible to beginners and experienced users alike. This accessibility has contributed to the mold's popularity, as it allows for a wide range of people to unleash their creativity and produce stunning perfume bottles.The company's dedication to customer satisfaction is evident in their support and resources for users of the Perfume Bottle Resin Mold. They offer guidance and assistance to anyone who may have questions or concerns about the product, ensuring that their customers are fully supported in their creative endeavors. This level of care and attention has not gone unnoticed, as many users have expressed their appreciation for the company's commitment to excellence.The Perfume Bottle Resin Mold is a testament to the company's ability to innovate and provide practical solutions for creative individuals. Its high-quality materials, affordable pricing, and user-friendly design make it a valuable asset for anyone looking to personalize their fragrance products. With the support and guidance of the company, users can confidently explore their creativity and produce stunning perfume bottles that stand out in the market.

High-Quality Mold Manufacturer for Trash Cans

Today, we are proud to announce a new partnership with a leading manufacturer of trash can molds. This collaboration aims to bring high-quality, innovative molds to the market and meet the growing demand for durable and efficient waste management solutions.The company, with a history spanning over 20 years, has established itself as a reputable and reliable supplier in the mold manufacturing industry. Their commitment to excellence and continuous innovation has made them a preferred choice for businesses seeking top-notch quality molds.With a state-of-the-art facility equipped with advanced machinery and a team of skilled professionals, the company has the capability to design and produce a wide range of molds to meet various specifications and requirements. Their expertise covers a diverse array of products, including household trash cans, industrial waste containers, recycling bins, and more.In addition to their manufacturing capabilities, the company also prides itself on its commitment to sustainability and environmental responsibility. They have implemented sustainable practices in their production processes, such as using recycled materials and reducing waste generation. This aligns perfectly with our own values as we strive to promote eco-friendly solutions in the waste management industry.Through this partnership, we aim to leverage the company's expertise and capabilities to expand our product offerings, enhance our manufacturing capabilities, and ultimately provide our customers with the best-in-class trash can molds. This collaboration will enable us to stay ahead of the curve and remain a competitive force in the market.We are confident that this partnership will yield exceptional results and contribute to the advancement of waste management technology. By combining our industry knowledge and customer insights with the manufacturer's technical prowess, we are well-positioned to deliver innovative and efficient solutions that meet the evolving needs of businesses and consumers.As we move forward with this collaboration, we are excited about the possibilities it presents. We see great potential for growth, diversification, and the exploration of new markets. With our shared commitment to excellence and customer satisfaction, we are poised to make a significant impact in the industry and set new standards for trash can mold manufacturing.In conclusion, the partnership with the leading manufacturer of trash can molds marks an important milestone for us. It reflects our dedication to delivering superior products and solutions to our customers, and our determination to stay at the forefront of industry trends. We are excited about the opportunities that lie ahead and look forward to the positive impact this collaboration will have on our business and the waste management sector as a whole.

High-Quality Pallet Moulds: Essential Equipment for Efficient Warehouse Operations

Pallet Moulds, a leading manufacturer of high-quality plastic injection moulds, has been making waves in the industry with its cutting-edge technology and innovative designs. The company, with over 20 years of experience, has gained a strong reputation for delivering top-notch moulds to its global client base.Specializing in the production of pallet moulds, Pallet Moulds has established itself as a frontrunner in the market. With a state-of-the-art manufacturing facility and a team of highly skilled engineers and technicians, the company is able to produce moulds that meet the exact specifications of its clients. Whether it's for standard pallet sizes or custom designs, Pallet Moulds has the expertise and capabilities to deliver top-quality moulds on time and within budget.One of the key factors that set Pallet Moulds apart from its competitors is its dedication to research and development. The company continuously invests in new technologies and processes to improve the quality and efficiency of its moulds. This commitment to innovation has enabled Pallet Moulds to stay ahead of the curve and offer its clients the latest advancements in mould design and manufacturing.Moreover, Pallet Moulds takes great pride in its strict quality control measures. Each mould undergoes rigorous testing to ensure that it meets the highest standards of durability and performance. By adhering to strict quality standards, the company has built a solid reputation for delivering moulds that are reliable and long-lasting.In addition to its technical expertise, Pallet Moulds also prioritizes customer satisfaction. The company works closely with its clients to understand their specific needs and provide personalized solutions. Whether it's a small order or a large-scale production run, Pallet Moulds is committed to delivering exceptional service and exceeding customer expectations.Furthermore, Pallet Moulds places a strong emphasis on sustainability. The company's manufacturing processes are designed to minimize waste and reduce environmental impact. By using eco-friendly materials and energy-efficient technologies, Pallet Moulds is dedicated to creating a more sustainable future for the industry.With a strong track record of success and a commitment to excellence, Pallet Moulds is poised to continue its growth and expansion in the global market. The company's dedication to quality, innovation, and customer satisfaction sets it apart as a leader in the plastic injection moulding industry.For businesses looking for reliable and high-quality pallet moulds, Pallet Moulds stands out as a trusted partner. With its advanced technology, skilled workforce, and unwavering commitment to excellence, the company is well-equipped to meet the demands of the ever-evolving industry.In conclusion, Pallet Moulds has solidified its position as a top-tier manufacturer of plastic injection moulds, with a focus on pallet moulds. With its dedication to innovation, quality, customer satisfaction, and sustainability, the company continues to set the standard for excellence in the industry. As Pallet Moulds continues to grow and expand its global presence, it remains a trusted and reliable partner for businesses seeking top-quality moulds for their operations.

Top Quality Runner Molding for Your Project Needs

Runner Molding, a renowned leader in the manufacturing and production of plastic injection molded parts, is making headlines as it continues to expand its operations and enhance its service offerings. Since its inception, Runner Molding has been dedicated to providing high-quality and precision-engineered plastic parts for a wide range of industries, including automotive, medical, consumer products, and electronics.With state-of-the-art facilities and a team of experienced engineers and technicians, Runner Molding has established itself as a trusted partner for companies seeking reliable and efficient plastic injection molding solutions. The company is committed to delivering superior products that meet the exact specifications and requirements of its clients, while also adhering to strict quality standards and regulations.Runner Molding's recent announcement of its expansion plans has caught the attention of industry insiders and potential clients alike. The company is investing in new equipment and technology to increase its production capacity and streamline its manufacturing processes. This expansion will allow Runner Molding to better serve its growing customer base and take on more complex and demanding projects.In addition to its commitment to cutting-edge technology and innovation, Runner Molding prides itself on its dedication to sustainability and environmental responsibility. The company has implemented sustainable practices throughout its operations, including the use of eco-friendly materials and energy-efficient manufacturing processes. Runner Molding's focus on sustainability not only benefits the environment but also resonates with clients who prioritize corporate social responsibility.Furthermore, Runner Molding places a strong emphasis on customer satisfaction and collaboration. The company works closely with its clients at every stage of the production process, from initial design and prototyping to final production and delivery. This collaborative approach ensures that the end product meets the client's expectations and specifications while also adhering to strict quality control measures.One of Runner Molding's key strengths is its ability to offer a wide range of customization options to its clients. Whether a client requires a small batch of specialized parts or a high-volume production run, Runner Molding has the expertise and capabilities to deliver. The company's team of skilled engineers can assist clients in optimizing their designs for manufacturability and cost-effectiveness, ensuring that the final product meets all performance and quality requirements.As Runner Molding continues to grow and expand its operations, the company remains committed to maintaining its high standards of excellence and customer satisfaction. With a focus on innovation, sustainability, and collaboration, Runner Molding is poised to remain a leader in the plastic injection molding industry for years to come.In conclusion, Runner Molding is a company that continues to set the standard for excellence in the plastic injection molding industry. With its dedication to innovation, sustainability, and customer satisfaction, Runner Molding is well-positioned to meet the evolving needs of its clients and the industry as a whole. As it continues to expand and enhance its capabilities, Runner Molding is sure to solidify its reputation as a trusted and reliable partner for companies seeking high-quality plastic injection molding solutions.

Ultimate Guide to Scientific Injection Molding for High-Quality Products

Scientific Injection Molding, also known as SIM, is a cutting-edge technology that has revolutionized the injection molding industry. By using advanced scientific principles and state-of-the-art equipment, SIM allows for more precise and efficient production of plastic parts. This technology has been widely adopted by manufacturers across various industries, and it has proven to be a game-changer in the world of plastic manufacturing.One company that has fully embraced the power of Scientific Injection Molding is {}. Founded in {}, {} is a leading provider of plastic injection molding services. The company has always prided itself on staying at the forefront of technological advancements in the industry, and their adoption of SIM has further cemented their position as an innovator in the field.{}The company’s expertise in SIM is unrivaled, thanks to their investment in cutting-edge equipment and their team of highly skilled engineers and technicians. By leveraging the power of Scientific Injection Molding, they are able to offer their clients a wide range of benefits, including:1. Enhanced Precision: SIM allows for tighter control over the molding process, resulting in parts with incredibly precise dimensions and specifications. This level of precision is essential for industries where accuracy is paramount, such as aerospace, automotive, and medical manufacturing.2. Improved Efficiency: By optimizing the molding process, SIM reduces production cycle times and minimizes material waste, leading to significant cost savings for clients. This efficiency also allows {} to meet tight deadlines and deliver high volumes of parts in a timely manner.3. Superior Quality: The advanced scientific principles behind SIM ensure that the molded parts are free from defects and imperfections, leading to higher overall quality and reliability. This is crucial for industries where safety and performance are non-negotiable.4. Design Flexibility: With SIM, {} can produce complex geometries and intricate designs that would be challenging or impossible to achieve with traditional molding methods. This opens up new possibilities for their clients and allows them to bring their innovative ideas to life.{}In addition to these benefits, {} has also focused on sustainability in their SIM processes. They have implemented eco-friendly materials and optimized their manufacturing processes to minimize environmental impact, aligning with the growing demand for sustainable manufacturing practices.{}The company’s commitment to excellence and continuous improvement has made them a trusted partner for businesses seeking high-quality plastic molding solutions. Whether it’s for prototyping, low-volume production, or large-scale manufacturing, {} has the expertise and capabilities to meet their clients’ needs.As the demand for precision, efficiency, and quality in plastic molding continues to rise, Scientific Injection Molding has become an indispensable technology for manufacturers around the world. With their dedication to mastering this cutting-edge approach and their track record of success, {} is well-positioned to lead the way in the exciting future of plastic injection molding. Their commitment to pushing the boundaries of what’s possible in their industry is a testament to their passion for innovation and their unwavering dedication to exceeding their clients' expectations.In conclusion, Scientific Injection Molding has truly transformed the way plastic parts are manufactured, and {} is at the forefront of harnessing its power to deliver exceptional results for their clients. With their expertise, dedication, and state-of-the-art capabilities, {} is poised to continue setting new standards of excellence in the world of injection molding.

Top Medical Injection Molding Companies Facilitating Advanced Healthcare Solutions

Medical Injection Molding Companies Revolutionizing Healthcare Sector In recent years, the rapid advancement of medical injection molding technology has revolutionized the healthcare sector, improving patient care and transforming the way medical devices are manufactured. One notable player in this field is a leading medical injection molding company, which has been at the forefront of innovation and has established itself as a trusted partner in the medical device industry. With its high-quality products, cutting-edge technology, and dedication to meeting customer needs, this company has become a key player in shaping the future of healthcare.Founded over two decades ago, this medical injection molding company has grown from a small operation to a global leader in its field. The company's success lies in its commitment to producing superior medical devices that meet the highest industry standards. By leveraging advanced injection molding techniques, they are able to manufacture intricate and precise components that are crucial for the functioning of medical devices.One of the company's greatest strengths is its state-of-the-art manufacturing facilities. Equipped with the latest technology, including advanced robotics and computer-aided design (CAD) systems, these facilities enable the company to produce a wide range of medical devices with unprecedented precision and efficiency. Additionally, strict quality control measures are in place throughout the manufacturing process to ensure that each product meets the rigorous standards set by regulatory bodies.Another key aspect that sets this company apart is its emphasis on research and development (R&D). The company invests heavily in R&D to stay ahead of industry trends and develop innovative solutions in collaboration with its customers. By working closely with medical professionals and understanding their specific needs, they are able to design and manufacture products that address critical healthcare challenges.In recent years, a growing trend within the medical device industry has been the shift towards miniaturization. This is where the expertise of medical injection molding companies becomes indispensable. Through precise injection molding techniques, these companies are able to produce complex, miniature components that are essential for the development of smaller, portable medical devices. This advancement has allowed for greater patient convenience, increased portability, and improved overall patient experience.The medical injection molding company understands the importance of sustainability and environmental responsibility. It employs various eco-friendly practices throughout its operations, such as the use of bio-based materials and recycling programs. By minimizing waste and reducing its carbon footprint, the company demonstrates its commitment to a greener future.Furthermore, this company prioritizes customer satisfaction and aims to build long-term partnerships. With a team of experienced engineers and designers, they offer comprehensive support to their clients, from product design and development to manufacturing and distribution. By providing customized solutions and maintaining open lines of communication, they ensure that their customers' unique needs are met.In conclusion, medical injection molding companies have played a crucial role in transforming the healthcare sector by providing advanced, high-quality medical devices. This leading medical injection molding company, with its dedication to innovation and commitment to customer satisfaction, has emerged as a key player in the industry. Through its state-of-the-art manufacturing facilities, emphasis on R&D, and focus on sustainability, the company continues to shape the future of healthcare. As technology continues to advance, we can expect further advancements from this company and others in the field, driving the healthcare sector to new heights.

Understanding the Process of Injection Molding

SHOT MOLDING: REVOLUTIONIZING MANUFACTURING PROCESSESIn today's fast-paced manufacturing industry, efficiency and precision are paramount. Companies are constantly seeking innovative ways to streamline their production processes and minimize waste. One such innovation that has revolutionized the industry is shot molding, a cutting-edge manufacturing technique that has the potential to reshape the way products are made.{Company} is at the forefront of this technological advancement, spearheading the adoption of shot molding in various industries. With a strong focus on innovation and continuous improvement, {Company} has positioned itself as a leader in the manufacturing sector, providing high-quality shot molding solutions to meet the diverse needs of its clients.So, what exactly is shot molding? Shot molding is a manufacturing process that involves injecting molten material, typically plastic, into a mold cavity. The mold is then cooled and solidified, resulting in the formation of a precise and intricate product. This process is highly versatile and can be used to produce a wide range of products, from small and intricate components to large and complex parts.The key to the success of shot molding lies in its ability to produce parts with exceptional precision and consistency. This not only reduces the need for post-processing and finishing but also ensures that each product meets the highest quality standards. Additionally, the high-speed nature of shot molding enables manufacturers to produce large quantities of parts in a relatively short period, significantly improving production efficiency.{Company} has fully embraced the potential of shot molding, incorporating state-of-the-art technology and equipment to offer comprehensive shot molding solutions. The company has invested heavily in research and development, continually refining its processes to deliver optimal results for its clients. By leveraging the latest advancements in shot molding technology, {Company} has been able to push the boundaries of what is possible, providing its customers with innovative and cost-effective solutions.The benefits of shot molding are far-reaching and have the potential to transform the manufacturing landscape. The ability to produce highly precise and intricate parts with minimal waste not only reduces production costs but also contributes to a more sustainable manufacturing process. With the demand for custom and complex components on the rise, shot molding offers a versatile and efficient solution that can meet the evolving needs of the industry.{Company} is committed to driving the widespread adoption of shot molding across various sectors, working closely with its clients to identify opportunities for optimization and improvement. The company's expertise and dedication to excellence have earned it a reputation as a trusted partner in the manufacturing industry, with a track record of delivering exceptional results.As the manufacturing industry continues to evolve, shot molding is poised to play a pivotal role in shaping the future of production processes. With its ability to deliver unparalleled precision, speed, and efficiency, shot molding is set to revolutionize the way products are made, offering manufacturers a powerful tool to enhance their competitiveness and drive innovation.In conclusion, shot molding represents a significant leap forward in manufacturing technology. The potential of this cutting-edge process is vast, and companies like {Company} are leading the charge in harnessing its power to deliver superior results for their clients. As the industry continues to embrace shot molding, it is clear that it has the potential to redefine the way products are manufactured, opening up new possibilities for innovation and progress.