Complete Guide to Two Plate Moulds

By:Admin

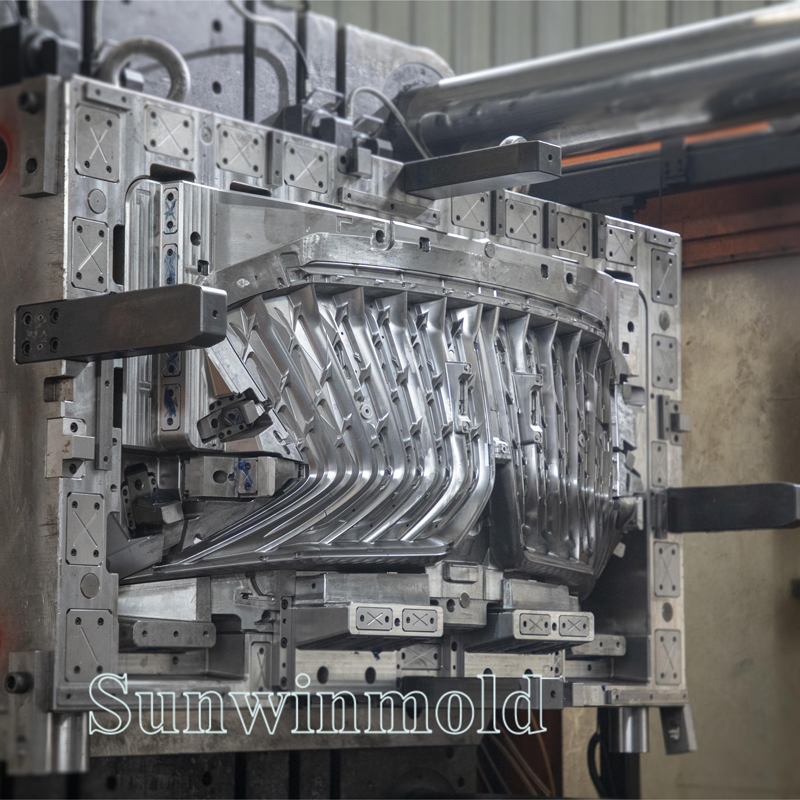

Two Plate Mould, a leading company in the mould and tooling industry, has recently introduced a new line of advanced technology for precision moulding. The company has been at the forefront of innovation in the industry for over two decades, and their latest offering promises to revolutionize the way precision moulding is done.

The new line of technology is designed to address the ever-increasing demand for high precision and efficiency in moulding processes. With the global manufacturing industry moving towards more complex and intricate designs, there is a growing need for moulds that can deliver on tight tolerances and intricate features. Two Plate Mould's new technology aims to meet these demands head-on.

The company's expertise in precision engineering and tooling has allowed them to develop moulds that can achieve superior accuracy and repeatability. This is crucial for industries such as automotive, aerospace, and medical devices, where even the slightest deviation from the design specifications can have serious ramifications.

One of the key features of Two Plate Mould's new technology is its ability to produce moulds with extremely fine details and intricate geometries. This is made possible through the use of advanced machining and EDM (Electrical Discharge Machining) processes, which allow for the creation of highly complex moulds with unparalleled precision.

In addition to their precision capabilities, Two Plate Mould's new technology also offers significant improvements in efficiency and lead times. The company has invested heavily in automation and digitalization, allowing for streamlined processes and reduced time-to-market for their customers.

Furthermore, Two Plate Mould's commitment to sustainability is evident in their new technology, with a focus on reducing material waste and energy consumption in the moulding process. By optimizing the design and manufacturing process, the company is able to deliver moulds that are not only more precise and efficient, but also more environmentally friendly.

The introduction of Two Plate Mould's new technology comes at a time when the global manufacturing industry is experiencing a period of rapid transformation. With the rise of Industry 4.0 and the Internet of Things, there is a growing emphasis on smart manufacturing and connected production systems. Two Plate Mould's new technology aligns with this trend, offering moulds that are compatible with smart manufacturing processes and can seamlessly integrate with digital production systems.

The company's new technology has already garnered attention from industry experts and early adopters, with many praising its capabilities and potential impact on the moulding industry. In a recent industry event, Two Plate Mould showcased their new technology to widespread acclaim, with many attendees expressing keen interest in integrating it into their own manufacturing processes.

Looking ahead, Two Plate Mould is committed to further refining and expanding their new technology, with a focus on continuously pushing the boundaries of precision and efficiency in the moulding industry. The company is also exploring opportunities for collaboration with other industry leaders to create innovative solutions that address the evolving needs of the manufacturing sector.

With their new line of advanced technology for precision moulding, Two Plate Mould is poised to set new standards for accuracy, efficiency, and sustainability in the industry. As the global manufacturing landscape continues to evolve, the company's commitment to innovation and excellence ensures that they will remain a key player in shaping the future of precision moulding.

Company News & Blog

High-Quality Perfume Mold Factories in China - Find Your Reliable Supplier Now

China Perfume Mold Factories: Leading the Way in High-Quality Perfume Packaging SolutionsChina has long been known for its excellence in manufacturing and production, and the perfume industry is no exception. With the increasing demand for high-quality perfume packaging solutions, China Perfume Mold Factories have emerged as leaders in the field, providing innovative and reliable products to companies around the world.With a strong focus on quality and customer satisfaction, China Perfume Mold Factories have garnered a reputation for excellence in the industry. They offer a wide range of perfume molds, including bottle molds, cap molds, and pump molds, all of which are designed to meet the highest standards of quality and precision. In addition to their standard line of products, they also provide custom mold design services, allowing their clients to create unique and personalized packaging solutions for their products.One of the key factors driving the success of China Perfume Mold Factories is their commitment to innovation and technology. They have invested heavily in state-of-the-art manufacturing equipment and processes, allowing them to produce molds with unparalleled accuracy and consistency. This dedication to innovation has allowed them to stay ahead of the competition and continue to meet the evolving needs of the perfume industry.Furthermore, China Perfume Mold Factories are known for their strict adherence to international quality standards. They use only the highest quality materials in their manufacturing processes, and each mold undergoes rigorous testing to ensure its durability and performance. This attention to detail has earned them the trust and loyalty of their customers, who rely on them to deliver top-notch products time and time again.Another key strength of China Perfume Mold Factories is their dedication to customer service. They understand the importance of building strong and lasting relationships with their clients, and they go above and beyond to provide exceptional support and assistance throughout the entire manufacturing process. From initial design consultations to final product delivery, they work closely with their clients to ensure that their needs are met and their expectations are exceeded.In addition to their commitment to quality and customer service, China Perfume Mold Factories also place a strong emphasis on sustainability and environmental responsibility. They have implemented eco-friendly manufacturing practices and are constantly seeking ways to reduce waste and minimize their carbon footprint. This commitment to sustainability has not only helped them reduce costs and increase efficiency but has also positioned them as leaders in the movement towards a more environmentally conscious industry.As the demand for high-quality perfume packaging solutions continues to grow, China Perfume Mold Factories are well-positioned to meet the needs of the global market. Their dedication to quality, innovation, and customer satisfaction has set them apart as leaders in the industry, and their continued success is a testament to their unwavering commitment to excellence.In conclusion, China Perfume Mold Factories have established themselves as a driving force in the perfume packaging industry, providing innovative and reliable products to companies around the world. With their focus on quality, innovation, and customer satisfaction, they have earned a reputation as leaders in the field and are well-positioned to meet the evolving needs of the global market. With their dedication to sustainability and environmental responsibility, they are not only shaping the future of perfume packaging but are also setting an example for the entire industry.

Injection Molding Process for Pet Plastic: A Complete Guide

**TO BE REMOVED BEFORE PUBLISHING**Pet Plastic Injection Molding is a leading technology in the field of plastic injection molding. The company has been providing high-quality, cost-effective plastic injection molding solutions for over 20 years and has gained a reputation for its innovation and dedication to customer satisfaction.Pet Plastic Injection Molding specializes in the manufacturing of precision plastic components for a wide range of industries, including automotive, electronics, medical, and consumer goods. The company's state-of-the-art facilities are equipped with the latest technology and machinery, allowing them to produce complex and intricate plastic parts with exceptional accuracy and efficiency.With a team of highly skilled engineers, designers, and technicians, Pet Plastic Injection Molding is able to provide end-to-end solutions, from design and prototyping to production and assembly. Their expertise and attention to detail ensure that every project is completed to the highest standards, meeting the exact specifications and requirements of their clients.One of the key advantages of Pet Plastic Injection Molding is their ability to work with a variety of materials, including PET, PP, PE, PVC, and more. This versatility allows them to cater to a diverse range of customer needs, whether it be for rigid containers, flexible packaging, automotive components, or medical devices.In addition to their technical capabilities, Pet Plastic Injection Molding is committed to sustainability and environmental responsibility. The company has implemented eco-friendly practices throughout their operations, from the efficient use of raw materials to the recycling and reuse of waste products. By prioritizing sustainability, they aim to minimize their environmental impact and contribute to a cleaner, greener future.Pet Plastic Injection Molding's dedication to quality and excellence has earned them the trust and loyalty of numerous clients worldwide. Their commitment to continuous improvement and innovation ensures that they stay at the forefront of the plastic injection molding industry, offering cutting-edge solutions that meet the evolving needs of the market.In line with their commitment to customer satisfaction, Pet Plastic Injection Molding offers personalized support and collaboration throughout every stage of the project. Their team works closely with clients to understand their needs, provide expert advice, and deliver customized solutions that exceed expectations. This customer-centric approach has earned them a reputation for reliability, responsiveness, and integrity.The company's success and reputation can be attributed to their unwavering dedication to quality, innovation, and customer satisfaction. They have consistently demonstrated their ability to meet the most demanding requirements of their clients, delivering exceptional results time and time again.In conclusion, Pet Plastic Injection Molding is a global leader in plastic injection molding, renowned for their technical expertise, commitment to sustainability, and customer-centric approach. With a track record of excellence spanning over two decades, they continue to set the standard for high-quality, precision plastic components. Whether it's for complex automotive parts or intricate medical devices, Pet Plastic Injection Molding is the go-to partner for reliable, cost-effective, and cutting-edge plastic injection molding solutions.

Create a Quality Cup Mould Basket Mold for Your Business

Cup Mould Basket Mold: A Revolutionary Addition to the Company's PortfolioThe global manufacturing industry is constantly evolving, with companies continually seeking innovative solutions to enhance their production processes. In line with this, (company name) has recently announced the launch of their latest product, the Cup Mould Basket Mold. This revolutionary addition to the company's portfolio is set to transform the way in which cups and baskets are manufactured, catering to a wide range of industries including food and beverage, automotive, and consumer goods.Established in (year), (company name) has earned a strong reputation as a leading manufacturer of precision moulds and tooling solutions. With a focus on delivering high-quality products that are tailored to meet the specific needs of their clients, the company has consistently pushed the boundaries of innovation in the manufacturing sector. The introduction of the Cup Mould Basket Mold is a testament to their commitment to providing cutting-edge solutions that drive efficiency and productivity for their customers.The Cup Mould Basket Mold is designed to revolutionize the production of cups and baskets, offering a versatile and highly efficient solution for manufacturers. With a focus on precision and durability, the mold is engineered to deliver exceptional performance, ensuring the consistent production of high-quality products. Its robust design and advanced features make it suitable for a wide range of applications, allowing manufacturers to streamline their production processes and achieve higher levels of output.One of the key highlights of the Cup Mould Basket Mold is its versatility. The mold is compatible with a variety of materials, including plastic, glass, and metal, providing manufacturers with the flexibility to cater to diverse market demands. Whether it's the production of disposable cups for the food and beverage industry or customized baskets for automotive components, the mold's adaptability makes it an ideal choice for businesses looking to expand their product offerings.In addition to its versatility, the Cup Mould Basket Mold also prioritizes efficiency and speed. Its innovative design incorporates advanced cooling and ejection systems, minimizing cycle times and maximizing productivity. This means manufacturers can significantly increase their output without compromising on the quality of the end product. Moreover, the mold's user-friendly interface and easy maintenance further contribute to its appeal, ensuring a seamless and hassle-free production process for operators.Furthermore, the introduction of the Cup Mould Basket Mold aligns with (company name)'s commitment to sustainability. The mold is engineered to optimize material usage and reduce waste, contributing to a more environmentally friendly manufacturing process. By enabling manufacturers to produce products with minimal material wastage, the mold supports the industry's transition towards more sustainable and eco-conscious practices.With the launch of the Cup Mould Basket Mold, (company name) is poised to set new benchmarks in the manufacturing industry. By leveraging their expertise in precision engineering and tooling solutions, the company aims to empower manufacturers with a game-changing tool that enhances their capabilities and drives growth. The mold's potential to revolutionize production processes and deliver tangible benefits to businesses underscores (company name)'s commitment to innovation and customer success.As the global manufacturing landscape continues to evolve, (company name) remains at the forefront, pioneering solutions that redefine industry standards. The introduction of the Cup Mould Basket Mold is a testament to the company's unwavering dedication to pushing the boundaries of what is possible in manufacturing. With its promise of efficiency, versatility, and sustainability, the mold is poised to make a lasting impact on the industry, cementing (company name)'s position as a trailblazer in precision tooling solutions.

High-Efficiency Blow Molding Machine: Latest Advancements in Bottle Manufacturing Technology

The Bottle Blow Molding Machine market is witnessing significant growth with the rising demand for plastic bottles across various industries such as food and beverages, pharmaceuticals, and personal care products. The need for efficient and high-speed manufacturing processes has led to the increased adoption of bottle blow molding machines, which are capable of producing a large number of bottles in a short period of time.One of the leading players in the bottle blow molding machine industry is {}. With over 20 years of experience in manufacturing and supplying blow molding machines, {} has established itself as a reliable and innovative company in the market. The company is known for its high-quality machines that are durable, efficient, and capable of meeting the diverse needs of its customers.{} offers a wide range of bottle blow molding machines, including fully automatic, semi-automatic, and stretch blow molding machines. These machines are designed to produce various types of bottles, such as PET bottles, HDPE bottles, and PP bottles, with different shapes and sizes. The company's machines are equipped with advanced technology and features that ensure high precision, consistency, and productivity in the bottle manufacturing process.One of the key strengths of {} is its commitment to continuous innovation and improvement in its product offerings. The company invests heavily in research and development to enhance its machine designs, optimize production processes, and incorporate new technologies to stay ahead of market trends. This dedication to innovation has enabled {} to provide its customers with state-of-the-art bottle blow molding machines that are efficient, cost-effective, and environmentally friendly.In addition to its focus on product innovation, {} is also known for its excellent customer service and support. The company has a team of highly skilled engineers and technicians who provide comprehensive technical assistance, installation, and maintenance services to ensure that its customers' machines operate at peak performance. This level of support has earned {} a strong reputation for reliability and customer satisfaction in the bottle blow molding machine industry.As a global player in the bottle blow molding machine market, {} has established a strong presence in various regions and countries around the world. The company's machines are widely used by manufacturers in the food and beverage, pharmaceutical, and personal care industries, among others. With a strong distribution network and partnerships with industry leaders, {} has been able to expand its reach and serve a diverse range of customers with varying production needs.Looking ahead, {} is poised to continue its growth and success in the bottle blow molding machine market. The company remains committed to delivering high-quality, innovative machines that meet the evolving demands of its customers and the industry as a whole. By staying at the forefront of technological advancements and maintaining its dedication to customer satisfaction, {} is well-positioned to remain a top choice for bottle blow molding solutions in the years to come.In conclusion, the bottle blow molding machine market is experiencing significant growth, driven by the increasing demand for plastic bottles across various industries. With its focus on innovation, quality, and customer support, {} has solidified its position as a leading player in the market. As the company continues to expand its global presence and enhance its product offerings, {} is poised for continued success and leadership in the bottle blow molding machine industry.

High-Quality Injection Moulding Items for Your Needs

Injection Moulding Items, a leading manufacturer in the plastic injection moulding industry, has been making a significant impact within the manufacturing sector. The company has been able to achieve this through their commitment to producing high-quality plastic components for a wide range of industries, including automotive, medical, consumer goods, and electronics. With their extensive experience and advanced technology, Injection Moulding Items has been able to set themselves apart from their competitors and establish themselves as an industry leader.Established in {year}, Injection Moulding Items has always been dedicated to providing superior products and services to their clients. Their state-of-the-art facilities are equipped with advanced machinery and technology, allowing them to meet the diverse needs of their customers. The company also employs a team of skilled engineers and technicians who are committed to delivering precision-engineered plastic components that meet the highest industry standards.One of the key aspects that sets Injection Moulding Items apart from their competitors is their ability to provide customized solutions to their clients. They work closely with their customers to understand their specific requirements and are able to develop and produce custom plastic components that meet their exact specifications. This level of customization has earned Injection Moulding Items a stellar reputation within the industry and has helped them to build long-standing relationships with their clients.The company's commitment to quality is evident in their rigorous quality control processes. Injection Moulding Items adheres to strict quality standards throughout the production process, ensuring that each plastic component that leaves their facility meets the highest quality benchmarks. This dedication to quality has earned them numerous certifications and accolades within the industry, further solidifying their position as a trusted and reliable manufacturer.In addition to their focus on quality, Injection Moulding Items also prioritizes sustainability in their manufacturing processes. They have implemented environmentally friendly practices within their facilities, including the use of recyclable materials and energy-efficient machinery. By minimizing their environmental impact, Injection Moulding Items is not only contributing to a healthier planet but also demonstrating their commitment to social responsibility.The company's extensive capabilities extend to a wide range of plastic injection moulding items, including but not limited to automotive components, medical devices, consumer goods, and electronic parts. Whether their clients require small, intricate components or large, complex parts, Injection Moulding Items has the expertise and technology to deliver. Their ability to manufacture a diverse range of products has made them an invaluable partner to businesses across various industries, further solidifying their position as a leading manufacturer in the plastic injection moulding industry.As Injection Moulding Items continues to grow and expand its capabilities, the company remains committed to maintaining its high standards of quality and customer service. With a focus on innovation and continuous improvement, Injection Moulding Items is poised to remain at the forefront of the plastic injection moulding industry for years to come.In conclusion, Injection Moulding Items has established itself as a leading manufacturer in the plastic injection moulding industry through its unwavering commitment to quality, customization, sustainability, and innovation. With a robust infrastructure, advanced technology, and a dedicated team, Injection Moulding Items is well-equipped to meet the diverse needs of its clients and maintain its position as an industry leader.

Growing Demand and Opportunities in the Injection Molding Industry Revealed by Latest News

[News Title]Injection Molding Industry Experiences Robust Growth Amid Technological Advancements[News Content]The injection molding industry has witnessed tremendous growth in recent years, thanks to the continuous advancements in technology. With the ability to produce complex and intricate parts with high precision and efficiency, injection molding has become a cornerstone in various sectors, ranging from automotive and packaging to electronics and healthcare.One of the leading players in this industry is a renowned company () that has been at the forefront of manufacturing top-quality injection molding machines. With its commitment to innovation and customer satisfaction, the company has revolutionized the industry and has played a pivotal role in its expansion.Established over two decades ago, () has carved a niche for itself by providing state-of-the-art injection molding machines tailored to meet diverse customer needs. Their machines offer exceptional durability and reliability while providing excellent performance and productivity. () has earned a stellar reputation for delivering top-notch products and exceptional customer service.Furthermore, the company's dedication to research and development has empowered them to continuously enhance their machinery's capabilities. By investing in the latest technologies and incorporating advanced features, () has been able to offer cutting-edge solutions that meet the ever-evolving demands of the injection molding industry.The injection molding industry has seen a surge in demand due to its ability to manufacture complex components with precision, reduce production costs, and streamline processes. () has played a critical role in this growth by providing manufacturers with high-quality and efficient machinery that ensures accurate and consistent production.The automotive industry has been a significant contributor to the expansion of the injection molding sector. With the growing demand for lightweight and eco-friendly vehicles, manufacturers are increasingly relying on injection molding techniques to produce various interior and exterior components. The machines provided by () have been instrumental in helping automotive manufacturers meet these demands, thanks to their precision, speed, and energy efficiency.Moreover, the packaging industry has also experienced a boost from the injection molding advancements. The ability to manufacture intricate and customized packaging solutions has bolstered the growth of this sector. Companies in the packaging industry are now able to produce durable, lightweight, and appealing packaging solutions using injection molding techniques. ()'s machines have played a vital role in enhancing the productivity and efficiency of packaging manufacturers, enabling them to cater to the evolving consumer preferences.The electronics industry has also relied heavily on injection molding to produce intricate and precise components required for various electronic devices. The miniaturization of electronic devices has necessitated the production of smaller and more intricate parts, making injection molding a preferred choice. () has provided manufacturers in the electronics industry with machines capable of producing high-precision components efficiently, creating a positive impact on their production capabilities.Furthermore, the healthcare sector has benefited immensely from injection molding techniques. The ability to produce sterile and high-quality medical devices and equipment has improved patient care and safety. ()'s state-of-the-art injection molding machines have been pivotal in facilitating the production of medical components while adhering to stringent quality control measures.The growing demand for quality goods coupled with the continuous advancements in the injection molding industry has positioned () as a leading player in the global market. With strong customer focus, technological expertise, and a commitment to innovation, () is set to empower manufacturers in different industries to achieve their production goals efficiently and sustainably.In conclusion, the injection molding industry is experiencing significant growth due to the continuous advancements in technology. Companies like () have played a vital role in revolutionizing the industry by providing innovative and high-quality machinery. With the ability to produce complex and precise components, injection molding has become an integral part of various sectors, including automotive, packaging, electronics, and healthcare. ()'s commitment to research and development, along with their exceptional customer service, has solidified their position as a prominent player in the global injection molding market.

Create Your Own Resin Mold for Perfume Bottles and Unleash Your Creativity

Perfume Bottle Resin Mold is a new product that has captured the attention of the market in recent months. This innovative mold has been designed to help create custom perfume bottles using resin, allowing for a unique and personalized touch to the final product. With its easy-to-use design and high-quality materials, the Perfume Bottle Resin Mold has quickly become a favorite among DIY enthusiasts and professionals in the fragrance industry.The Perfume Bottle Resin Mold is manufactured by a leading company in the arts and crafts industry. Their commitment to quality and innovation has led to the development of a wide range of products that cater to the needs of creative individuals. With a strong emphasis on user-friendly designs and durable materials, the company has established itself as a trusted name in the market.The Perfume Bottle Resin Mold is a testament to the company's dedication to providing innovative solutions for creative projects. It is crafted with precision and attention to detail, ensuring that users can create flawless perfume bottles with ease. The mold is made from high-quality materials that are resistant to wear and tear, allowing for multiple uses without compromising on the end result.One of the key features of the Perfume Bottle Resin Mold is its versatility. It can be used to create a wide variety of perfume bottle designs, from sleek and modern to intricate and decorative. This flexibility has made it a valuable tool for artists and designers who are looking to add a personal touch to their fragrance products. Whether it's for personal use or commercial production, the Perfume Bottle Resin Mold offers endless possibilities for customization.The company behind the Perfume Bottle Resin Mold is dedicated to ensuring that their products are accessible to all. They have made it a priority to keep their prices competitive, without compromising on quality. This commitment to affordability has made the Perfume Bottle Resin Mold an attractive option for businesses and individuals alike, as they seek to create unique and memorable fragrance products.In addition to its high-quality materials and affordable pricing, the Perfume Bottle Resin Mold is also designed for ease of use. It comes with clear and simple instructions, making it accessible to beginners and experienced users alike. This accessibility has contributed to the mold's popularity, as it allows for a wide range of people to unleash their creativity and produce stunning perfume bottles.The company's dedication to customer satisfaction is evident in their support and resources for users of the Perfume Bottle Resin Mold. They offer guidance and assistance to anyone who may have questions or concerns about the product, ensuring that their customers are fully supported in their creative endeavors. This level of care and attention has not gone unnoticed, as many users have expressed their appreciation for the company's commitment to excellence.The Perfume Bottle Resin Mold is a testament to the company's ability to innovate and provide practical solutions for creative individuals. Its high-quality materials, affordable pricing, and user-friendly design make it a valuable asset for anyone looking to personalize their fragrance products. With the support and guidance of the company, users can confidently explore their creativity and produce stunning perfume bottles that stand out in the market.

Top Quality Industrial Crate Moulds Made in China: Expert Insights

China's Industrial Crate Mould - A Revolutionary Solution for the Manufacturing SectorAs the manufacturing sector continues to evolve, companies are continuously seeking innovative solutions to enhance efficiency and streamline their operations. One such solution that has gained significant attention is the China Industrial Crate Mould. This revolutionary moulding technology has transformed the manufacturing process, offering numerous benefits to companies across various industries.China has long been recognized as a global manufacturing powerhouse, and the introduction of the Industrial Crate Mould is further strengthening this status. By eliminating the need for traditional manufacturing methods, such as welding and joining, this mould offers unparalleled ease and efficiency in production.The Industrial Crate Mould offers remarkable design flexibility, allowing manufacturers to create customized and intricate designs for a wide range of industrial crates. These crates are widely used in sectors such as logistics, transportation, warehousing, and more, making them a crucial component of supply chain management. With the advancement of the Industrial Crate Mould, manufacturers can now produce crates of superior quality, meeting the demands of various industries.One of the key advantages of the Industrial Crate Mould is its cost-effectiveness. Traditional manufacturing methods often require significant investment in machinery, labor, and maintenance. The introduction of this mould eliminates these expenses, as it operates on advanced automated systems and requires minimal human intervention. This streamlined production process not only reduces costs but also enhances the overall productivity of manufacturing units.Furthermore, the Industrial Crate Mould guarantees uniformity and consistency in the manufacturing process. With precise measurements and standardized production techniques, manufacturers can ensure that every crate produced meets the highest quality standards. This eliminates the risk of human error and ensures that the final product is reliable, sturdy, and durable.The Industrial Crate Mould is a significant step towards sustainable manufacturing practices. By utilizing eco-friendly materials and minimizing waste generation, this mould addresses the growing concerns of environmental degradation. Its advanced features allow for maximum material utilization, reducing waste and promoting sustainable manufacturing principles.In addition to its environmental benefits, the Industrial Crate Mould also offers improved safety features. Traditional manufacturing processes, such as welding, pose significant safety hazards to workers. The use of advanced moulding technology eliminates the need for such hazardous operations, ensuring a safer working environment for employees.China's Industrial Crate Mould has gained widespread recognition and popularity in the global market. With its state-of-the-art technology and efficient production capabilities, it has become a preferred choice for companies worldwide. This mould not only enhances manufacturing efficiency but also helps businesses meet stringent quality requirements.Leading companies in China's mould manufacturing industry, such as [Company Name], have made significant contributions to the development and advancement of the Industrial Crate Mould. With their expertise and innovative approach, these companies have paved the way for a more efficient and sustainable manufacturing sector.In conclusion, the introduction of the China Industrial Crate Mould has revolutionized the manufacturing process. Offering numerous benefits such as cost-effectiveness, design flexibility, improved safety, and environmental sustainability, this mould has become an indispensable tool for companies across various industries. As the manufacturing sector continues to evolve, the Industrial Crate Mould is poised to play a pivotal role in shaping the future of manufacturing worldwide.

Understanding the Importance of Top Cap Molding in Manufacturing Processes

Top Cap Molding, a leading manufacturer in the plastic molding industry, has been making waves with their top-of-the-line products and exceptional customer service. Established in 2005, the company has quickly risen to prominence, earning a stellar reputation within the industry for their high-quality molding solutions.Specializing in the production of top caps for a variety of industries, Top Cap Molding prides itself on their ability to provide custom molding services to meet the unique needs of their clients. With a state-of-the-art manufacturing facility and a team of highly skilled engineers and technicians, the company is able to deliver top-notch products that exceed industry standards.One of the key factors that sets Top Cap Molding apart from their competitors is their unwavering commitment to quality. The company places a strong emphasis on using the latest technology and the best materials in their manufacturing processes, ensuring that their products are durable, reliable, and built to last. In addition, their strict quality control measures guarantee that every product that leaves their facility meets the highest standards of excellence.Furthermore, Top Cap Molding is dedicated to providing exceptional customer service. The company takes a collaborative approach with their clients, working closely with them to understand their specific requirements and develop tailored solutions that meet their exact needs. Their responsive and knowledgeable sales team is always available to address any inquiries and provide guidance throughout the entire process, from initial consultation to final product delivery.In recent news, Top Cap Molding has announced the launch of a new line of top caps that are specifically designed to meet the growing demand for sustainable and eco-friendly packaging solutions. The company has invested heavily in research and development to create top caps that are made from recycled materials, without compromising on quality or performance. This new product line is a testament to Top Cap Molding's commitment to innovation and environmental responsibility."We are thrilled to introduce our new line of sustainable top caps," said the CEO of Top Cap Molding. "As a company, we recognize the importance of reducing our environmental footprint and offering eco-friendly alternatives to our clients. We believe that these new top caps will not only benefit the planet, but also provide our customers with a superior and sustainable packaging solution."The introduction of this new product line has been well-received by industry experts and customers alike, with many applauding Top Cap Molding for their forward-thinking approach and dedication to sustainability. The company's innovative efforts have positioned them as a leader in the industry, setting a new standard for eco-friendly packaging solutions.Looking ahead, Top Cap Molding is poised to continue its upward trajectory, with plans to further expand their product offerings and enhance their manufacturing capabilities. With a focus on excellence, innovation, and customer satisfaction, the company is well-positioned to remain a top contender in the plastic molding industry.In conclusion, Top Cap Molding has solidified its position as a premier manufacturer of top caps, delivering top-quality products and unparalleled customer service. Their recent launch of sustainable top caps underscores their commitment to environmental stewardship and sets a new benchmark for eco-friendly packaging solutions. With a steadfast dedication to quality and a progressive approach to innovation, Top Cap Molding is undoubtedly a force to be reckoned with in the industry.

Efficient and Affordable Bottle Blow Molding Machine for Pet Bottles

PET Bottle Blow Molding Machine Brings Revolutionary Advancements to the Packaging IndustryIn today's fast-paced consumer market, the demand for efficient and high-quality packaging solutions has never been higher. As the need for reliable and sustainable packaging continues to grow, companies are constantly searching for innovative technologies to meet these demands. This is where the PET Bottle Blow Molding Machine comes into play, revolutionizing the packaging industry with its advanced technology and exceptional performance.The PET Bottle Blow Molding Machine, provided by a leading manufacturing company in the industry, is a state-of-the-art solution designed to meet the growing demand for high-quality PET bottles. The machine boasts an impressive array of features that set it apart from traditional blow molding machines, making it a game-changer in the packaging industry.One of the key features of the PET Bottle Blow Molding Machine is its advanced automation technology, which allows for seamless and efficient operation. This technology ensures that the entire manufacturing process is streamlined and optimized, resulting in higher productivity and lower production costs. Additionally, the machine is equipped with a user-friendly interface, making it easy for operators to monitor and control the production process with precision and accuracy.Furthermore, the PET Bottle Blow Molding Machine offers exceptional versatility, allowing for the production of a wide range of bottle sizes and designs. Whether it's for carbonated drinks, water, or other beverages, the machine can accommodate various production requirements, making it a versatile solution for companies in the packaging industry.In addition to its impressive features, the PET Bottle Blow Molding Machine also prioritizes sustainability and environmental responsibility. With the increasing focus on sustainable packaging solutions, this machine offers a significant reduction in energy consumption and material waste, making it an eco-friendly choice for companies looking to minimize their environmental impact.The company behind the PET Bottle Blow Molding Machine has a long-standing reputation for delivering high-quality and reliable packaging solutions to its clients. With a focus on continuous innovation and technological advancement, the company has become a trusted partner for businesses looking to enhance their packaging capabilities and remain competitive in the market.Furthermore, the company's commitment to customer satisfaction is unmatched, offering comprehensive support and servicing to ensure that clients get the most out of their investment in the PET Bottle Blow Molding Machine. From installation and training to ongoing maintenance and technical assistance, the company is dedicated to providing a seamless and positive experience for its customers.The introduction of the PET Bottle Blow Molding Machine is poised to transform the packaging industry, offering businesses a cutting-edge solution to meet the growing demand for high-quality and sustainable packaging. With its advanced technology, exceptional performance, and commitment to customer satisfaction, this machine is set to become a staple in the production processes of companies across various sectors.As the market continues to evolve and consumer preferences shift towards sustainable and reliable packaging solutions, the PET Bottle Blow Molding Machine stands as a beacon of innovation and progress in the industry. With its ability to streamline production processes, reduce environmental impact, and deliver outstanding results, this machine is set to make a significant impact on the future of packaging.